Hydraulic systems power critical machinery across construction, agriculture, and manufacturing. At the heart of their efficiency lies a small but vital component: the hydraulic quick coupler. These devices streamline operations, yet misunderstandings about their capabilities and maintenance can lead to costly downtime. In this guide, we’ll demystify quick couplers—covering their function, pressure limits, types, leakage causes, and proven solutions.

What Does a Hydraulic Quick Coupler Do?

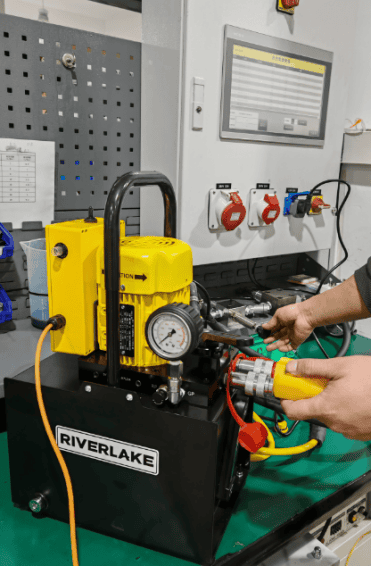

Hydraulic quick couplers enable rapid, tool-free connection and disconnection of fluid lines. They eliminate the need for time-consuming threading or wrenching, allowing operators to swap attachments (e.g., excavator buckets, grapples, or hydraulic tools) in seconds. Key benefits include:

- Reduced Downtime: Minimize machine idle time during tool changes.

- Containment: Prevent hydraulic fluid loss and environmental contamination.

- Safety: Lower physical strain and spill-related hazards.

Common Applications: Excavators, tractors, industrial presses, and material handling systems.

Pressure Ratings: How Much Can They Handle?

Pressure ratings define the maximum continuous operating pressure (in psi or bar) a coupler can withstand without failure. Typical ranges include:

- Standard Couplers: 3,000–5,000 psi (200–350 bar)

- High-Pressure Models: Up to 10,000 psi (700 bar) for specialized industrial use.

- Ultra-High Pressure Models:Up to 36,259 psi(2500bar) for ultra-high pressure industrial use.

Critical Factors Influencing Ratings:

- Material: Steel couplers outperform brass in high-pressure/durability applications.

- Seal Quality: Nitrile (NBR) or Viton® seals resist heat/chemical degradation.

- Design: Flat-face couplers often handle higher pressures than poppet types.

Safety Tip: Always select a coupler with a pressure rating 25–50% higher than your system’s maximum operating pressure.

Types of Hydraulic Quick Couplers

- Poppet-Type Couplers:

- Mechanism: Spring-loaded poppet valve opens upon connection.

- Pros: Low cost, widely compatible.

- Cons: Fluid spillage during disconnect; vulnerable to contamination.

- Flat-Face Couplers (ISO 16028):

- Mechanism: Sealed connection with zero fluid loss.

- Pros: Ideal for eco-sensitive sites (e.g., agriculture, food processing).

- Cons: Higher cost; require precise alignment.

- Locking Styles:

- Ball-Lock: Quick-connect with rolling balls; faster but prone to wear.

- Sleeve-Lock: Sliding collar mechanism; more durable but slower engagement.

- Connection Methods:

- Threaded: Secure but labor-intensive.

- Push-to-Connect: Rapid installation; best for lower-pressure systems.

Why Do Hydraulic Quick Couplers Leak?

Leaks compromise efficiency, safety, and environmental compliance. Top causes include:

- Worn Seals/O-Rings: Degraded by heat, pressure cycles, or incompatible fluids.

- Contamination: Dirt, metal shavings, or moisture scoring sealing surfaces.

- Misalignment: Bent stems or improper coupling causing uneven seal pressure.

- Mechanical Damage: Cracked housings, scratched poppets/balls, or corroded threads.

- Overpressure/Temperature: Exceeding design limits deforms seals.

How to Stop Quick Coupler Leaks: Proactive Solutions

- Preventive Maintenance:

- Inspect seals quarterly; replace every 1–2 years (or per OEM guidelines).

- Always use dust caps/plugs when couplers are disconnected.

- Correct Installation & Handling:

- Align couplers straight; never force connections.

- Follow torque specs to avoid thread damage.

- Seal Management:

- Use chemically compatible seals (e.g., Viton® for high-temp/petroleum fluids).

- Lubricate O-rings with hydraulic fluid only—grease attracts contaminants.

- Contamination Control:

- Adhere to ISO 4406 fluid cleanliness standards.

- Install in-line filters; use flush-face couplers in dusty environments.

- Timely Replacement:

- Upgrade to flat-face couplers if spillage is unacceptable.

- Replace couplers showing wear, stiffness, or leakage—never repair damaged units.

Conclusion

Hydraulic quick couplers are indispensable for operational agility—but only when correctly selected and maintained. Prioritize pressure compatibility, choose the right type (flat-face for zero-spill; poppet for cost-efficiency), and implement rigorous contamination control. Most leaks stem from preventable issues: seal wear, dirt ingress, or misalignment. By adopting proactive maintenance and training your team on proper coupling procedures, you’ll maximize uptime and system longevity.

When in doubt, consult coupler manufacturers for application-specific guidance—especially for extreme pressures or specialty fluids.