Introduction

Why do bolts fail even when tightened “correctly”? The answer often lies in a critical misunderstanding: confusing torque with tension. While these terms are sometimes used interchangeably, they describe fundamentally different physical phenomena. For engineers, technicians, and DIY enthusiasts, grasping this distinction is essential for designing safe structures, preventing equipment failures, and ensuring precision in mechanical assemblies. Let’s demystify these concepts and explore their real-world implications.

1. What is Tension?

Tension is a linear pulling force acting axially (along the axis) of an object. It stretches or elongates materials, creating resistance against separation.

Key Characteristics:

- Direction: Unidirectional (e.g., pulling a rope).

- Units: Newtons (N) or pounds-force (lbf).

- Measurement: Directly via load cells or strain gauges.

Real-World Examples:

- Suspension bridge cables resisting gravitational loads.

- Tension springs storing mechanical energy.

- Bolts preloaded to clamp joint surfaces.

Why It Matters:

Tension determines structural integrity. Insufficient tension in a bolt can cause joint slippage; excessive tension risks fracture.

2. What is Torque?

Torque is a rotational force (or moment) that causes angular acceleration around an axis. It does not directly stretch objects but twists them.

Key Characteristics:

- Direction: Perpendicular to the axis of rotation (e.g., turning a wrench).

- Units: Newton-meters (Nm) or pound-feet (lb-ft).

- Measurement: Torque wrenches or sensors.

Real-World Examples:

- Tightening a bolt with a wrench.

- An engine crankshaft converting combustion force into rotation.

- Electric motors generating rotational output.

Why It Matters:

Torque drives motion and enables fastener tightening but is an indirect measure of clamp load.

3. Torque vs. Tension: Key Differences

| Aspect | Torque | Tension |

|---|---|---|

| Nature | Rotational force (twisting) | Linear force (stretching) |

| Direction | Acts perpendicular to the axis | Acts parallel to the axis |

| Primary Units | Nm, lb-ft | N, lbf |

| Effect | Causes rotation/bending | Causes elongation |

| Measurement Tools | Torque wrench, transducer | Load cell, ultrasonic sensor |

4. The Critical Relationship in Fastening

Torque and tension intersect critically in bolted joints:

- Torque is the input: The force applied via a wrench.

- Tension is the output: The resulting axial stretch (preload) in the bolt.

The Torque-Tension Formula:

Tension (F) = Torque (T) / (K × D)

K: Friction coefficient (typically 0.1–0.3).D: Bolt diameter.

Why Accuracy Eludes Us:

- Up to 90% of applied torque overcomes friction (thread/head friction).

- Only ~10% converts to usable tension.

- Variables like lubrication, surface roughness, and thread damage dramatically affect results.

5. Consequences of Confusion

- Under-Torquing:

- Low tension → Joint separation, vibration loosening, fatigue failure.

- Over-Torquing:

- Excessive tension → Bolt yielding, fracture, or thread stripping.

- Real-World Case:

Automotive lug nuts require precise torque specs. Too little torque risks wheel detachment; too much warps brake rotors.

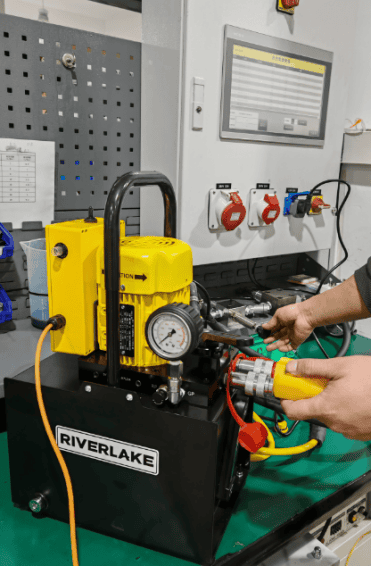

6. Measuring Torque vs. Tension

| Force | Measurement Methods |

|---|---|

| Torque | – Calibrated torque wrenches. – In-line sensors (e.g., ultrasonic pulse reflection). |

| Tension | – Direct: Load cells, strain gauges. – Indirect: Torque-to-yield (TTY) fasteners (stretch bolts). |

7. When to Prioritize Each

- Focus on Torque:

- Rotational systems (e.g., gearboxes, drive shafts).

- Initial fastener tightening (practical field applications).

- Focus on Tension:

- Critical joints (e.g., pressure vessels, aerospace structures).

- Long-term reliability studies (e.g., bridge bolt preload monitoring).

Conclusion

Torque and tension are inseparable partners in mechanics—yet fundamentally distinct. Torque is the rotational force you apply; tension is the axial stretch you achieve. Confusing them risks catastrophic failures, while mastering their relationship unlocks precision, safety, and efficiency. As a rule of thumb: “Torque controls tension, but tension secures the joint.”