As hydraulic engineers, we routinely encounter joints demanding immense, precisely controlled torque. Standard tools fall short here. and the hydraulic torque wrench plays an important role as the cornerstone of safety and accuracy in high-torque bolting applications across our industry. This blog delves into the technical essence, application spectrum, variations, leading brands, operational protocols, and troubleshooting of these indispensable tools.

1. What is a Hydraulic Torque Wrench?

A hydraulic torque wrench is a powered torque tool that utilizes hydraulic pressure to generate a controlled, high-torque rotational force (output torque) for tightening or loosening bolts and nuts. Its core principle is Pascal’s Principle(you can read more about pascal’s principle here) and hydraulic amplification:

- Hydraulic Power Source: A hydraulic pump (hand-operated, electric, or air-driven) generates high-pressure hydraulic fluid flow.

- Hydraulic Hose: Transmits the pressurized fluid to the wrench body (also called the hydraulic torque wrench drive unit).

- Hydraulic Motor / Actuator: Within the wrench body, the pressurized fluid drives a hydraulic piston(s) or motor. This converts hydraulic energy into linear or rotational mechanical force.

- Torque Amplification & Output: The piston/motor drives a ratcheting mechanism or directly rotates an output drive (square drive or hexagon socket). The wrench’s internal geometry (lever arm length, piston area, gear reduction if present) amplifies the hydraulic force into high, precisely measurable output torque.

- Reaction Point: A critical component! The wrench body braces (reacts) against a fixed point (another bolt head, a reaction fixture, or the structure itself) to prevent the entire tool from spinning uncontrollably. This reaction force is essential for applying torque to the fastener.

Key Advantages:

- Extremely High Torque Output: Capable of generating thousands of foot-pounds (ft-lbs) or Newton-meters (Nm) of torque.

- Precision & Accuracy: Achieves highly accurate and repeatable torque values (typically ±3% or better), crucial for critical flanges, structural joints, and pressure vessels.

- Reduced Operator Effort: Hydraulic power does the heavy lifting, minimizing physical strain and fatigue.

- Safety: Controlled application and reaction point reduce risks associated with high-torque operations (e.g., slipping, uncontrolled tool rotation).

- Accessibility: Low-profile designs can reach confined spaces inaccessible to large impact wrenches.

2. Application of a Hydraulic Torque Wrench

Hydraulic torque wrenches are essential wherever precise, high-torque bolting is required, particularly in:

- Flange Bolting: Critical in oil & gas (pipelines, wellheads, refineries, offshore platforms), petrochemical, and power generation for pressure-containing flanges (ASME B16.5, API 6A).

- Wind Turbines: Tower section bolts, blade bolts, gearbox, and generator mounting bolts.

- Heavy Machinery: Mining equipment, excavators, crushers, large presses.

- Construction & Structural Steel: Erection of bridges, high-rise buildings, crane assembly (ASTM A325/A490 bolts).

- Marine & Shipbuilding: Engine mounts, propeller shafts, deck machinery, hull sections.

- Power Transmission: Turbine-generator sets, large motor mounts, transformer bushing connections.

- Mining: Mill liners, crusher mantles, large conveyor drive pulleys.

- Aerospace (Ground Support): Engine mounting bolts, landing gear components.

Core Requirement: Applications demanding controlled, documented, and repeatable high torque.

3. Types of Hydraulic Torque Wrenches

The two primary classifications are based on drive mechanism and profile:

- Square Drive Hydraulic Torque Wrenches:

- Mechanism: Utilize a hydraulic piston acting on a lever arm connected to a ratcheting mechanism. The ratchet drives a standard square drive (e.g., ¾”, 1″, 1½”).

- Output: High torque output capability.

- Use: Require sufficient clearance above the fastener for the ratchet head to engage and swing. Best suited for applications with moderate space constraints where the socket can swing freely.

- Advantages: Often higher torque capacity for size, readily available standard sockets.

- Disadvantages: Larger head profile, requires swing arc clearance.

- Low-Profile Hydraulic Torque Wrenches:

- Mechanism: Utilize a hydraulic motor (often planetary gear driven) coupled directly to a hexagon drive socket or a drive lug that engages the nut/bolt head directly.

- Output: Designed for high torque in confined spaces. Torque range varies significantly by model.

- Use: Ideal for extremely tight spaces where a swinging ratchet head won’t fit (e.g., closely spaced bolts on large flanges, inside casings). Operate with minimal radial clearance.

- Advantages: Minimal radial clearance required, no swing arc needed. Highly versatile in congested bolting patterns.

- Disadvantages: Can have a larger axial profile, specialized sockets/drive lugs often required.

4. Major Hydraulic Torque Wrench Brands (Representative Examples)

The market features established global leaders known for quality, reliability, and technical support:

- Hydratight (Actuant / Enerpac): A pioneer and one of the largest global players, offering extensive ranges of both square drive and low-profile wrenches, pumps, and accessories.

- Norbar Torque Tools: Renowned for high-quality, innovative tools, including a strong range of hydraulic torque wrenches and calibration services.

- SPX FLOW (Power Team): Offers robust hydraulic torque wrench systems under the Power Team brand, known for durability.

- Atlas Copco (formerly Chicago Pneumatic): Provides a comprehensive line of industrial bolting tools, including hydraulic torque wrenches.

- Hytorc (Unex): A major force, particularly known for their advanced low-profile bolting systems and intelligent controllers.

- Wren (formerly Wren Hydraulic Equipment): Specializes in high-capacity hydraulic torque wrenches and tensioners.

- ULTPRE:manufactures a comprehensive range of high-performance Hydraulic Torque Wrenches, engineered for excellence in demanding industrial applications.

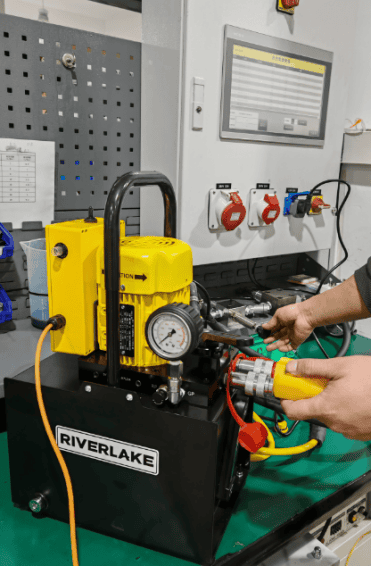

- RIVERLAKE:hydraulic torque wrenches represent high-performance bolting solutions engineered for critical industrial applications requiring extreme torque accuracy and reliability.

- Rad Torque Systems: Known for innovative designs, particularly in battery-powered and digital torque tools, also offering hydraulic options.

Selection Consideration: Prioritize torque range, drive size, required profile (square drive vs. low-profile), pump compatibility, accuracy needs, service support, and budget. Consult manufacturer technical specifications rigorously.

5. How to Use a Hydraulic Torque Wrench: A Procedural Overview

Safety First! Always wear appropriate PPE (safety glasses, gloves, steel-toe boots). Ensure the work area is secure.

- Planning & Setup:

- Identify the required torque value and tightening sequence/pattern (e.g., star pattern for flanges per ASME PCC-1 or OEM spec).

- Select the correct wrench type, drive size, and torque capacity.

- Select the correct hardened socket or drive lug that fits the fastener snugly. Ensure it’s rated for the torque.

- Choose the appropriate hydraulic pump unit. Ensure pump pressure rating and flow capacity match the wrench requirements.

- Inspect all components: wrench, hoses, fittings, pump, sockets/lugs for damage, leaks, or wear. Calibration is critical – ensure the wrench/pump/gauge system is within its calibration period.

- Calculate the required hydraulic pressure to achieve the target torque using the wrench manufacturer’s calibration chart or formula (Torque = Pressure x Tool Factor). If using a digital controller, program the target torque.

- Tool Positioning:

- Fit the socket or drive lug securely onto the fastener.

- Position the wrench body so its reaction point is firmly and safely braced against a fixed, immovable surface (e.g., another bolt head designed as a reaction point, a dedicated reaction pad, or structural steel). Critical: Ensure the reaction point is secure and will not slip, shear, or damage the structure. Verify the reaction direction matches the torque direction.

- Connect the hydraulic hoses between the pump and wrench. Ensure quick-connect couplers are fully engaged and clean.

- Applying Torque:

- Operate the pump control lever/switch to pressurize the system.

- The wrench will drive the fastener. Observe the pressure gauge or digital display.

- For square drive wrenches: The wrench will ratchet. Release pressure after each stroke, reposition the wrench head if necessary for the next stroke, and re-apply pressure. Repeat until the wrench no longer strokes (indicating the fastener isn’t turning further under that pressure).

- For low-profile wrenches: They typically drive continuously until pressure is released or the target torque is reached (if using a controller).

- Stop applying pressure when the target pressure/torque is reached. Do not “hold on” at maximum pressure unnecessarily.

- Release the pump pressure to de-pressurize the system completely.

- Post-Operation:

- Move to the next fastener in the specified sequence.

- After completing the joint, perform multiple passes (typically 2-3) following the sequence, progressively increasing torque to the final value. This ensures even load distribution.

- Disconnect hoses, remove the wrench, and store components properly. Relieve any residual pressure in the hoses before disconnecting.

6. Hydraulic Torque Wrench Troubleshooting

Common issues and potential causes:

- Wrench Fails to Achieve Torque / Lacks Power:

- Low Hydraulic Pressure: Pump malfunction, internal pump leak, pressure relief valve stuck open, insufficient pump capacity, low fluid level, air in system (cavitation), leaking hoses/fittings.

- Wrench Internal Failure: Worn or damaged piston seals, internal leakage, damaged ratchet mechanism (square drive), worn motor/gears (low-profile).

- Incorrect Setup: Using the wrong tool factor/calculation, incorrect pump/wrench pairing, slipping socket/lug, inadequate reaction (wrench slipping).

- Fastener Issue: Fastener seized, galled threads, incorrect lubrication.

- Wrench Leaks Hydraulic Fluid:

- Damaged or worn O-rings/seals (at hose connections, cylinder head, piston).

- Cracked housing.

- Loose fittings/hose connections.

- Damaged hydraulic hoses.

- Wrench Doesn’t Hold Pressure / Drops Under Load:

- Internal leak in the wrench (piston seals, valve).

- Internal leak in the pump (check valves, piston seals).

- External leak (hose, fitting).

- Air in the hydraulic system.

- Wrench Doesn’t Stroke (Square Drive) or Drive (Low-Profile):

- No Pressure: Pump failure, closed valve, disconnected hose, no fluid.

- Mechanical Jam: Debris in ratchet mechanism, damaged gears, seized bearing.

- Directional Valve Issue: Stuck or malfunctioning (on reversible wrenches).

- Overload: Fastener torque requirement exceeds wrench capacity or is seized.

- Inaccurate Torque Output:

- System Out of Calibration: Wrench, pump gauge, or transducer requires calibration. This is the most common cause of accuracy drift.

- Friction Losses: Excessive hose length, kinked hoses, dirty fluid increasing system resistance.

- Reaction Issues: Wrench slipping or deflecting during operation, absorbing energy.

- Operator Error: Incorrect pressure calculation, misreading gauge.

- “Phantom Torque” (Fastener feels tight but measured torque is low):

- High friction in threads/under nut face (insufficient or incorrect lubrication).

- Dirt, debris, or damage on threads or bearing surfaces.

- Cross-threaded fastener.

Troubleshooting Approach:

- Visual Inspection: Check fluid level, obvious leaks, damaged hoses/fittings, secure connections, socket/lug fit, reaction point stability.

- Verify Basics: Ensure correct pump operation, pressure setting, tool factor calculation, and calibration status.

- Isolate Components: If possible, test the pump with a different known-good wrench or a pressure gauge. Test the suspect wrench on a different known-good pump system.

- Listen & Feel: Unusual noises (cavitation, grinding) or vibrations can indicate problems.

- Consult Manuals: Refer to the manufacturer’s troubleshooting guide.

- Professional Service: For internal leaks, mechanical failures, or calibration, send the tool to an authorized service center. Never disassemble critical hydraulic components in the field unless specifically trained and authorized.

Conclusion

The hydraulic torque wrench is an indispensable tool for the professional hydraulic engineer and bolting technician. Its ability to deliver precise, high torque with safety and repeatability makes it critical for the integrity of countless industrial connections. Understanding its principles, types, proper usage protocols, and maintenance/troubleshooting requirements is paramount for ensuring successful and safe bolted joint assembly. Always prioritize manufacturer guidelines, rigorous calibration, and safe operating procedures.