Introduction: The Heart of Hydraulic Systems

In industrial machinery, construction equipment, and aerospace systems, hydraulic pumps serve as the undisputed “heart” of power transmission. These critical components convert mechanical energy from engines or motors into hydraulic energy (fluid flow + pressure), enabling precise control of force and motion. Failure risks are severe: A degraded pump in a 20-MPa excavator system can cause over 40% loss in efficiency, triggering cascading actuator failures and unplanned downtime costing upwards of $10k/hour in heavy industries. This guide examines pump mechanics, classification, diagnostic protocols, and engineering-led maintenance strategies to maximize operational lifespan.

I. Working Principle: Precision Energy Conversion

Hydraulic pumps operate on Pascal’s Law, where mechanical force applied to confined fluid generates uniform pressure. The energy conversion sequence involves:

- Suction Phase:

- As the pump’s cavity (gear teeth, piston chamber, or vane slot) expands, volume increases create a vacuum (pressure ↓).

- Atmospheric pressure then pushes fluid from the reservoir into the pump via the inlet valve.

- Compression/Discharge Phase:

- Cavity volume decreases, rapidly compressing trapped fluid.

- Pressure spikes force fluid past the outlet check valve into the hydraulic circuit.

Key Physics:

- Volumetric efficiency = Actual Flow Rate / Theoretical Flow Rate × 100%.

- Critical failure point occurs when fluid viscosity or air ingress reduces below 85%.

II. Comprehensive Classification of Hydraulic Pumps

A. By Core Mechanism & Structure

Table 1: Structural Pump Types & Performance Limits

| Type | Pressure Range | Vol. Efficiency | Advantages | Limitations |

|---|---|---|---|---|

| Gear Pump | ≤25 MPa | 80–90% | Debris-tolerant; Low-cost | High noise; Pressure pulsations |

| Vane Pump | ≤21 MPa | 85–95% | Low noise; Steady flow | Sensitive to contamination |

| Piston Pump | ≤70 MPa | 92–98% | High-pressure capability | Complex; Requires ultra-clean oil |

| Screw Pump | ≤15 MPa | 75–85% | Ultra-smooth flow | Limited pressure tolerance |

- Gear Pumps: Use meshing gears (external/internal). Ideal for agricultural machinery due to dirt tolerance.

- Vane Pumps: Utilize rotor-mounted sliding vanes. Excel in CNC machines where noise suppression is critical.

- Axial Piston Pumps: Feature pistons reciprocating in parallel bores. Dominate in hydraulic presses (35–70 MPa).

B. By Power Source & Mobility

*Table 2: Power-Driven Pump Configurations*

| Type | Drive Mechanism | Flow-Pressure Range | Use Cases |

|---|---|---|---|

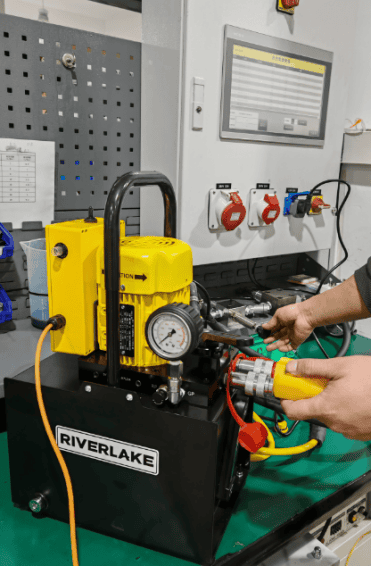

| Manual Hydraulic | Hand lever/crank | ≤5 L/min @ ≤10 MPa | Emergency jacks; Maintenance |

| Electric | AC/DC motor (0.5–100 kW) | 1–500 L/min @ ≤70 MPa | Factory automation |

| Pneumatic | Compressed air (6–10 bar) | ≤30 L/min @ ≤25 MPa | Explosive environments |

| Gasoline Powered | ICE engines (5–50 HP) | 10–200 L/min @ ≤40 MPa | Remote field operations |

| Battery Electric | Li-ion packs (24–48V) | 2–50 L/min @ ≤30 MPa | Solar farm actuators |

III. Common Failures & Engineering-Led Repairs

*Table 3: Symptom-Based Diagnosis & Corrective Actions*

| Failure Symptom | Root Causes | Repair Protocol |

|---|---|---|

| Low Pressure | Worn seals; Valve plate erosion | Replace O-rings; Polish/groove valve plates |

| Erratic Flow | Contaminated oil; Vane wear | Flush system; Install hardened vanes |

| Overheating | Internal bypassing; High viscosity | Verify relief valve; Switch to ISO VG 46 oil |

| Cavitation Noise | Clogged inlet filter; Low oil level | Clean/replace filters; Top up reservoir |

| Shaft Seal Leakage | Misalignment; Abrasive particles | Realign drive; Install lip seals with dust excluders8 |

Critical Repair Notes:

- Gear Pumps: Replace bushings if radial clearance >0.1 mm.

- Piston Pumps: Re-plate cylinder blocks if scoring depth exceeds 5µm.

- Post-repair validation requires 3-stage pressure cycling (20% → 60% → 100% P<sub>rated</sub>).

IV. Proactive Maintenance Framework

Extend pump life by 200% with these evidence-based practices:

- Oil Management:

- Maintain NAS Class 8 cleanliness (ISO 4406).

- Change filters when ΔP > 3 bar.

- Calibration Schedule:ApplicationCalibration IntervalTests RequiredGeneral Industry12 monthsFlow decay; Pressure rippleHigh-Pressure Systems6 monthsFull ISO 4409 validationPost-Failure RepairImmediatelyFlow decay + NPSH test

- Predictive Monitoring:

- Vibration analysis (ISO 10816): Alert if >4.5 mm/s RMS.

- Quarterly thermography: Flag components >90°C.

Conclusion: Optimizing Reliability Through Physics-Driven Maintenance

Hydraulic pumps fail not from use, but from contamination, misalignment, and neglected calibration. By adopting:

- Mechanism-specific diagnostics (e.g., flow decay tests for piston pumps)

- Power-source-matched duty cycles (e.g., avoiding gasoline pumps in enclosed spaces)

- ISO-compliant oil stewardship

Engineers can achieve >95% pump uptime. Remember: 70% of hydraulic system costs stem from energy loss—a high-efficiency piston pump cuts this by 25%. Invest in precision; it pays in kilowatts saved and downtime avoided.