In high-pressure piping systems, a misaligned flange isn’t just an inconvenience—it’s a catalyst for leaks, vibration-induced fatigue, catastrophic gasket failure, and safety incidents. Yet, many teams still rely on “eyeballing” or basic straightedges for alignment. This blog explores why specialized flange alignment tools are non-negotiable, the types available, and how to use them correctly to ensure integrity, safety, and compliance with standards like ASME PCC-1.

Why Specialized Flange Alignment Tools Are Critical

Human vision cannot detect misalignments under 0.5mm—yet industry tolerances often demand precision within this range. Without dedicated tools:

- Gaskets fail prematurely due to uneven compression.

- Bolt stress escalates by up to 300%, accelerating fatigue.

- Leak risks surge, especially in toxic/flammable service.

Tools eliminate guesswork, ensuring flanges mate perfectly before bolt tightening begins.

Types of Flange Alignment Tools

1. Mechanical Pin-Style Tools

- Design: Steel alignment pins/clamps + dial indicators.

- Best for: Small-to-medium flanges (≤24″), non-critical services.

- Pros: Rugged, low-cost, no power required.

- Cons: Manual calculations needed; limited precision (±0.1mm).

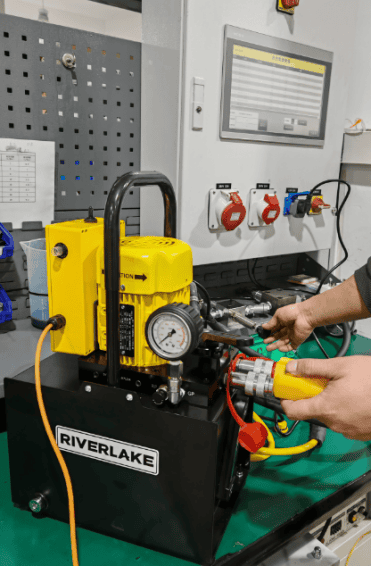

2. Hydraulic/Pneumatic Systems

- Design: Hydraulic rams with force gauges + reaction arms.

- Best for: Large/heavy flanges (e.g., 48″ Class 1500+).

- Pros: Generates >100 tons of force; remote operation.

- Cons: Requires pump/compressor; overkill for small flanges.

3. Laser Alignment Systems

- Design: Laser emitters + receivers + digital display/software.

- Best for: Critical applications (offshore, nuclear, pharma).

- Pros: Micron-level accuracy (±0.01mm); real-time data logging.

- Cons: Higher cost; training required.

Example: Pruftechnik’s Optalign Smart exports reports for compliance audits.

4. Combination Kits

Hybrid systems (e.g., FlangeAlign) merge mechanical pins with digital sensors—balancing accuracy and affordability.

How to Use a Flange Alignment Tool: Step-by-Step

(Adapt based on tool type; this covers a standard pin-style system)

Phase 1: Safety & Preparation

- Isolate and depressurize the line (follow LOTO procedures).

- Drain residual fluid and ventilate confined spaces.

- Clean flange faces rigorously—debris causes 40% of alignment errors.

- Install 2-4 temporary studs (or alignment pins) at 3/9 o’clock positions.

Phase 2: Tool Setup

- Mount alignment arms/clamps symmetrically onto studs.

- Attach dial indicators (radial and angular).

- Zero all gauges with flanges loosely held.

Phase 3: Measure Misalignment

- Radial Misalignment (Offset):

Rotate indicators around flange circumference. Record deviations at 12, 3, 6, and 9 o’clock. - Angular Misalignment (Gap):

Insert feeler gauges at 90° intervals. Max gap variance ≤0.2mm per ASME PCC-1.

Phase 4: Correct Misalignment

- Use hydraulic jacks or adjustment bolts to nudge flanges.

Pro Tip: Correct angular misalignment first. - Apply force gradually—avoid flange face damage.

- Monitor dial indicators continuously until values fall within tolerance.

Phase 5: Verification & Bolt-Up

- Re-check alignment after corrections.

- Follow cross-pattern bolt tightening (ASME PCC-1 sequence).

- Torque in 3 incremental passes (30%, 70%, 100%).

- Remove tools; perform final visual inspection.

Best Practices & Pro Tips

- Never final-tighten bolts before alignment—rework costs 10x more.

- For thermal lines, align at operating temperature or compensate for expansion.

- Combine laser measurement with hydraulic tools for heavy-flange precision.

- Train teams on all tool types—misuse voids warranties and compromises safety.

Common Mistakes to Avoid

❌ Skipping face cleaning: Even 0.05mm debris disrupts alignment.

❌ Ignoring angularity: Focusing only on radial offset causes uneven gasket crush.

❌ Over-torquing adjustment tools: Can crack flange faces.

❌ Neglecting calibration: Gauges drift—recalibrate quarterly.

Selecting the Right Tool

| Scenario | Recommended Tool |

|---|---|

| Small flanges, low budget | Mechanical pin-style |

| >24″ flanges, high force | Hydraulic system |

| API/ASME compliance tracing | Laser alignment |

| Mixed applications | Combination kit |

Top Brands: RIVERLAKE (hydraulic), Fluke (laser), Nord-Lock (mechanical).

Conclusion

Flange alignment isn’t a “nice-to-have”—it’s the bedrock of leak-free, safe, and efficient piping systems. Investing in the right tool reduces downtime by up to 30% and extends gasket life by 2–3x. Whether you choose mechanical pins or laser-guided systems, precision alignment pays for itself in safety, compliance, and operational continuity.