For modern construction company, the choice between precast concrete and cast-in-place (CIP) concrete directly impacts the performance of buildings being made. Both methods serve critical roles in infrastructure, yet their differences in production, installation, and longevity dictate their suitability for specific projects.

What is Precast Concrete?

Precast concrete (PC) refers to standardized concrete elements manufactured off-site in controlled factory conditions using mechanized processes. Unlike traditional cast-in-place concrete poured on-site, precast components are cured, finished, and transported to construction sites for assembly. This method leverages high-precision formwork and industrial quality control, resulting in consistent mechanical properties and dimensional accuracy.

The Precast Concrete Process: Factory Precision Meets Site Efficiency

- Design & Mold Preparation: Custom molds are fabricated based on structural drawings. Steel reinforcement cages are precisely positioned within molds.

- Concrete Pouring & Compaction: High-strength mixes (e.g., C60 or ULCC) are poured and vibrated to eliminate air voids.

- Controlled Curing: Components cure in temperature- and humidity-regulated chambers, accelerating strength development.

- Finishing & Quality Checks: Surfaces are smoothed, and compliance with strength/durability standards is verified.

- Transport & Installation: Using trucks and crane, components are positioned and connected via grouted sleeves or welded joints.

Advantages of Precast Concrete: Speed, Quality, and Sustainability

- Accelerated Construction: Reduces on-site timelines by 30–50% since foundation work and fabrication occur concurrently.

- Enhanced Durability: Factory curing achieves optimal hydration, yielding >100-year lifespans in high-performance mixes .

- Cost Efficiency: Reusable molds lower formwork expenses, while reduced labor and shorter schedules cut overheads.

- Sustainability: 17% lower HVAC energy use in buildings due to thermal mass; 30% lower transport emissions with lightweight ULCC mixes.

Disadvantages: Logistics and Design Constraints

- Transport Limitations: Heavy components restrict factories to a <200-mile economic radius.

- Storage Challenges: Large yard space needed for component stockpiling.

- Connection Complexity: Requires skilled crews for seismic-resistant joints; improper installation risks structural integrity.

Applications and Lifespan: Bridges, Highways, and Beyond

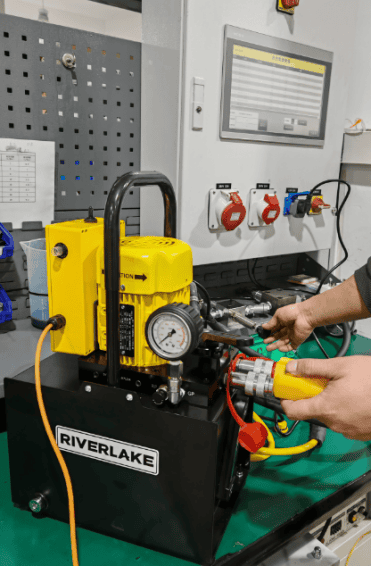

- Bridge Decks & Beams: Rapid replacement using hydraulic lifting systems minimizes traffic disruption.

- Railroad Crossings: Heavy-duty integrated crossing panels (10–15 years lifespan; extendable to 60 years with epoxy coatings).

- Modular Buildings: Lightweight foam concrete panels reduce dead loads and enable vertical expansion.

Table 1: Precast Concrete Performance Metrics

| Parameter | Standard PC | High-Performance PC |

|---|---|---|

| Lifespan | 50–70 years | 100+ years |

| Installation Speed | 2× faster than CIP | 3–4× faster |

| CO₂ Reduction | 15% lower vs. CIP | 30% lower (ULCC mixes) |

| Typical Uses | Culverts, barriers | Thin-shell roofs, seismic walls |

What is Cast-in-Place Concrete?

Cast-in-place (CIP) concrete is poured, formed, and cured directly on-site. This method creates continuous monolithic structures ideal for complex geometries and high-load applications like bridge piers or irregular foundations.

The CIP Process: Flexibility On-Site, Challenges in Control

- Formwork Assembly: Temporary molds (wood/steel) are built on-site.

- Reinforcement Fixing: Rebar cages are tied in place, often with prestressing tendons.

- Concrete Pouring & Compaction: Concrete is pumped into forms and vibrated. Hydraulic jacks tension tendons in post-tensioned applications.

- Curing & Protection: Water curing or membranes prevent plastic shrinkage cracks—critical for mass pours.

- Formwork Stripping: Forms are removed after achieving target strength (typically 7–14 days).

Advantages of CIP: Monolithic Integrity and Adaptability

- Seamless Load Transfer: Continuous structures outperform segmented precast in seismic zones.

- Design Freedom: Accommodates non-modular layouts (e.g., curved walls, variable-thickness slabs).

- Reduced Logistics: Eliminates transport/storage of large components.

Disadvantages: Labor, Time, and Quality Risks

- Extended Timelines: Curing adds 20–30 days to critical paths.

- Cracking Vulnerability: Thermal shrinkage in mass pours requires cooling pipes or admixtures.

- High Labor/Formwork Costs: Scaffolding and skilled crews constitute 30–40% of project expenses.

Applications and Lifespan: Where Monolithic Strength Matters

- High-Rise Cores: Shear walls with embedded utilities (kitchens, bathrooms).

- Heavy Foundations: Dam footings or turbine bases requiring continuity.

- Prestressed Bridges: Post-tensioned box girders for 40m+ spans.

Lifespans typically reach 50–75 years but drop to 10–12 years in corrosive environments without protective coatings.

*Table 2: Cast-in-Place Concrete Use Cases and Limitations*

| Scenario | Advantage | Risk Mitigation |

|---|---|---|

| Seismic Zones | Superior energy dissipation | Use steel fiber reinforcement |

| Massive Pours | No weak joints | Internal cooling + retarders |

| Complex Geometry | No connection constraints | BIM-guided formwork |

Key Differences Between Precast and Cast-in-Place Concrete

The choice between precast concrete and cast-in-place (CIP) concrete fundamentally impacts construction efficiency, structural performance, and project economics. Below are the critical distinctions:

1. Production Method & Location

- Precast Concrete:

- Manufactured off-site in climate-controlled factories.

- Components are cast in reusable molds, steam-cured, and transported to the site.

- Cast-in-Place Concrete:

- Poured, formed, and cured directly on-site.

- Requires temporary formwork assembled in the field.

2. Quality Control

- Precast:

- Superior consistency due to factory conditions (±2mm dimensional tolerance).

- Optimized curing achieves 28-day strength in 24 hours.

- CIP:

- Vulnerable to weather, labor skill, and on-site variables.

- Higher risk of honeycombing, cracking, or cover inadequacy.

3. Construction Speed

- Precast:

- Parallel fabrication (factory) and site prep reduce timelines by 30–50%.

- Instant assembly upon delivery (e.g., bridge decks installed in hours).

- CIP:

- Sequential processes: formwork → pouring → curing (7–28 days) → stripping.

- Weather delays compound schedule risks.

4. Structural Behavior

- Precast:

- Discontinuous system: Relies on mechanical/grouted connections.

- Potential weak points at joints in seismic zones.

- CIP:

- Monolithic continuity: Ideal for load redistribution and dynamic loads.

- No connection vulnerabilities.

5. Design Flexibility

- Precast:

- Limited to modular, repetitive geometries (beams, panels, slabs).

- Custom molds increase cost and lead time.

- CIP:

- Accommodates complex/irregular shapes (curved walls, variable thickness).

- Rebar placement adapts to real-time design changes.

6. Cost Structure

| Factor | Precast | Cast-in-Place |

|---|---|---|

| Labor | 20–30% lower (factory automation) | 30–40% of project cost |

| Formwork | Reusable steel molds (long-term savings) | Single-use timber/steel (high waste) |

| Transport & Logistics | 10–15% added cost (crane + transport) | Negligible |

| Repairs/Maintenance | Lower (controlled quality) | Higher (crack remediation) |

7. Sustainability

- Precast:

- 15–30% lower CO₂ emissions (optimized mixes + reduced site waste).

- Recyclable molds and steel reinforcement.

- CIP:

- Higher material waste (formwork off-cuts, concrete overpour).

- Potential for local material sourcing reduces transport emissions.

8. Lifespan & Durability

- Precast:

- 75–100+ years (factory curing ensures low permeability).

- Consistent cover depth protects reinforcement.

- CIP:

- 50–75 years (highly dependent on curing quality).

- Vulnerable to early-age cracking and corrosion in harsh environments.

Key Decision Criteria

- Choose Precast When:

- Speed is critical (e.g., highway overpasses, repetitive housing).

- Tight tolerance is required (e.g., industrial floors, facade panels).

- Site space/logistics are constrained.

- Choose CIP When:

- Structural continuity is non-negotiable (e.g., seismic cores, dams).

- Designs are unique or geometrically complex.

- Local material sourcing offsets cost disadvantages.

Conclusion: Context Dictates the Choice

Precast prioritizes predictability and speed; CIP delivers adaptability and continuity. Hybrid systems (e.g., precast columns + CIP cores) increasingly merge both advantages.