1. Introduction: The Concrete Revolution

Concrete dominates modern construction but harbors a critical flaw: exceptional compressive strength paired with dismal tensile resistance. This weakness causes cracks under load, shortening structural lifespans.Prestressing – the game-changing technique of pre-compressing concrete to counteract service loads. By permanently embedding internal compression forces, engineers create structures that defy conventional limits: longer spans, thinner sections, and crack-free performance. Two distinct pathways achieve this:

- Pre-Tensioning (PreT): Steel tensioned before concrete placement

- Post-Tensioning (PT): Steel tensioned after concrete hardening

Understanding their nuances unlocks next-level structural design.

2. Pre-Tensioning:

How It Works

Tendons are stretched between massive abutments (75-80% ultimate tensile strength). Concrete is cast around them. Once hardened (~35 MPa strength), tendons are released – transferring stress to concrete via bond mechanism.

Critical Process Steps:

- Tendon anchoring in casting beds

- Hydraulic jacking (force monitored by load cells)

- Concrete pouring and steam curing

- Controlled tendon release (thermal cutting or gradual hydraulic release)

Dominant Applications:

- 🏭 Precast hollow-core slabs (30% faster installation)

- 🛤️ Railway sleepers (e.g., UK HS2 project: 2.5 million units)

- ⚡ Concrete poles (60m spans without sagging)

Advantages:

- ✅ 40% lower production cost vs. PT (no anchors/grouting)

- ✅ Superior quality control in factory environments

- ✅ Minimal long-term maintenance

Limitations:

- ❌ Max span: 40m (practical limit for transportable elements)

- ❌ Inflexible tendon profiles (linear only)

- ❌ End-zone cracking risk during destressing

3. Post-Tensioning:

Core Principle:

Concrete is cast with embedded ducts. After curing, tendons are threaded, tensioned against hardened concrete, and locked with anchors. Grout injection provides corrosion protection.

Types of PT Systems:

| System Type | Mechanism | Best For |

|---|---|---|

| Bonded PT | Grout-filled ducts; full composite action | Bridges, nuclear containments |

| Unbonded PT | Grease-coated strands in HDPE sheaths | Parking decks, slabs |

| External PT | Tendons outside concrete section | Seismic retrofits |

| Segmental PT | Ducts aligned in precast segments | Cable-stayed bridge decks |

Essential Tools & Equipment:

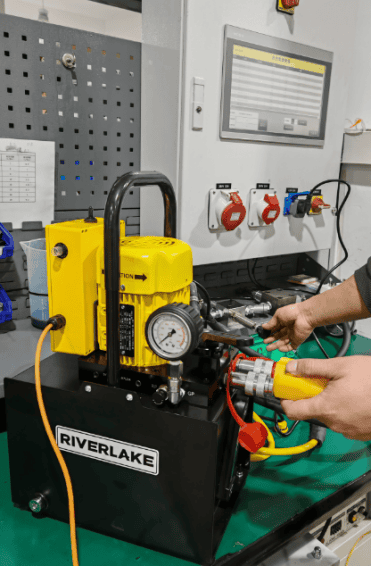

- Tools:

- 150–400 tons Capacity Hydraulic Stressing Jacks & Hydraulic Hoses

- Dual-control systems (pressure + elongation) with ±3% accuracy,Brands: VSL SC-1030, DYWIDAG ETS 1500

- Hydraulic Power Packs

- Grout Equipment:

- Colloidal mixers (1,500 rpm shear for void-free grout)

- Vacuum-assisted pumps (0.5–0.7 MPa injection pressure)

- Digital Monitoring:

- Wireless load cells (e.g., StrainSense PT-Monitor)

- BIM-integrated force tracking (AutoCAD/Revit plugins)

Critical Process Risks:

- ⚠️ Grout voids → Corrosion (Florida’s Niles Channel Bridge collapse)

- ⚠️ Anchor slippage (requires 150% proof-load testing)

- ⚠️ Friction losses in curved tendons (up to 25% force loss)

4. Head-to-Head Comparison: Which is Better?

| Parameter | Pre-Tensioning | Post-Tensioning | Engineering Verdict |

|---|---|---|---|

| Cost | $18–25/m² | $35–50/m² | PreT wins for budget projects |

| Span Capability | ≤40m | ≥150m (e.g., Rio–Antirrio Bridge) | PT dominates megastructures |

| Construction Speed | 5 days/cycle (factory) | 14–21 days/slab (site) | PreT 3x faster |

| Seismic Performance | Brittle failure risk | Energy dissipation via tendon yielding | PT superior in seismic zones |

| Maintenance | Low (fully encapsulated steel) | High (grout defect inspection) | PreT lowers lifecycle cost |

Decision Matrix:

- ✅ Choose PreT when: Mass-producing standard elements (slabs/beams), budget-driven, tight quality control needed.

- ✅ Choose PT when: Designing complex geometries (curved bridges), retrofitting, or pushing span limits beyond 50m.

5. Innovation Frontiers

Materials Revolution:

- CFRP Tendons: Carbon-fiber-reinforced polymers (e.g., Leadline®) – 70% lighter, corrosion-immune

- Shape Memory Alloys: Nitinol wires that “self-tension” when heated (University of Michigan trials)

Digital Transformation:

- AI Grout Void Detection: Ultrasound tomography + machine learning (98% accuracy vs. 70% manual)

- Digital Twins: Live monitoring of tendon forces (e.g., Singapore’s Marina Bay Suites PT slabs)

Sustainability Impact:

- ♻️ 30% less concrete vs. RC structures → 8,000 tons CO₂ saved in a mid-rise tower

- 📉 100-year design life → 60% lower lifecycle emissions

6. Landmark Case Studies

PreT Success:

- Hong Kong International Airport Runway: 120,000 PreT slabs installed in 18 months. Zero cracking after 10+ years.

PT Engineering Marvel:

- Burj Khalifa (Dubai): 45,000 m³ PT mat foundation withstands 600,000-ton vertical load.

- Millau Viaduct (France): Segmental PT deck spans 2.5km across valleys.

PT Failure Lesson:

- San Francisco International Airport Garage: Unbonded tendon corrosion → $120 million repair. Root cause: HDPE sheath damage during installation.

7. Conclusion:

Pre-tensioning delivers unbeatable efficiency for standardized elements, while post-tensioning enables architectural marvels once deemed impossible. Choose PreT for economics; embrace PT for impossibility.