Introduction: The Silent Giant Among Us

Imagine a construction crane effortlessly lifting 50 tons of steel, or a garbage truck compacting waste with the force of a dinosaur’s bite. This isn’t magic – it’s hydraulics in action. At the heart of these modern marvels lies a 370-year-old principle so fundamental that it shapes our world invisibly: Pascal’s Law. Let’s unravel how this unassuming law of physics enables tiny human inputs to move mountains.

I. Pascal’s Principle: The Bedrock Equation

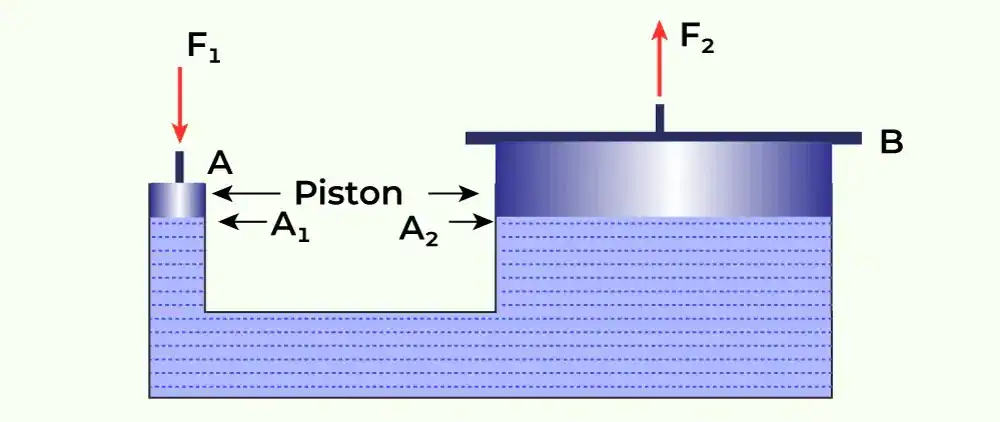

In 1653, French scientist Blaise Pascal made a revolutionary observation:

“Pressure applied anywhere to an enclosed incompressible fluid transmits equally in all directions throughout the fluid.”

This translates to a mathematical certainty:

P1 = P2 or F1/A1=F2/A2

The Golden Rule of Force Multiplication:

- Small force (

F₁) on small area (A₁) creates pressure (P) - Same pressure (

P) acts on larger area (A₂) → Larger force (F₂)!

Visualize this: A 10-lb child standing on a syringe (1 in²) connected to a piston (10 in²). The pressure (10 psi) becomes 100 lbs of lifting force at the piston – enough to hoist an adult!

II. The Hydraulic Force Multiplier: How It Works

The Components:

- Incompressible Fluid (Usually oil)

- Unlike gases, liquids won’t shrink under pressure

- Acts as a “solid force transmitter”

- Sealed System (No leaks = no pressure loss)

- Two Pistons (Different sizes = mechanical advantage)

The Trade-Off:

While force increases proportionally to area ratio, distance decreases inversely. If A₂ = 10 × A₁, the large piston moves only 1/10th the distance of the small one. Energy is conserved (Work = Force × Distance), but force is amplified where needed.

III. Real-World Superpowers: Hydraulics in Action

| Application | How Pascal’s Law Applies | Force Multiplication |

|---|---|---|

| Car Brakes | Light foot pedal → High-pressure fluid → Massive clamp force | 5x to 10x |

| Hydraulic Press | 50-ton metal bending with button-push precision | Up to 100x |

| Jaws of Life | Gentle hydraulic pump → 20,000 lbs of cutting force | 300x+ |

| Excavators | Operator’s joystick moves 50-ton buckets smoothly | 40x+ |

Construction Insight: The Caterpillar 349F excavator uses hydraulic pressure equivalent to 5,000 psi to swing its 20-ton arm – all controlled by joysticks translating finger movements into Herculean force.

IV. Why Liquids? The Critical Role of Fluids

Hydraulics fails with gases (Boyle’s Law: gases compress!). Liquids dominate because:

- Near-zero compressibility (Oil compresses <0.5% at 3,000 psi)

- Self-lubricating (Reduces wear)

- Heat transfer capability (Dissipates friction heat)

Fun Fact: Early 18th-century hydraulics used water, but mineral oil became standard post-WWII for its viscosity stability and corrosion resistance.

V. Engineering Challenges: No Free Lunch

Pascal’s Law has limitations smart engineers overcome:

- Leaks = Pressure loss → Precision seals & reinforced hoses

- Friction → Energy loss (up to 25% in complex systems)

- Fluid Dynamics → Turbulence at high speeds requires optimized routing

- Heat Management → Coolers prevent viscosity breakdown

Pro Tip: Aerospace hydraulics use phosphate ester fluids that resist combustion – critical when a jet engine is on fire!

VI. Beyond Pascal: Supporting Principles

Hydraulic systems integrate other physics laws:

- Conservation of Energy

- Input work = Output work (+losses)

- Bernoulli’s Principle

- Governs fluid speed/pressure in valves & pumps

- Continuity Equation

- Flow rate consistency (

Q = A × v)

- Flow rate consistency (

VII. Why Hydraulics Beats Electrics for Heavy Lifting

| Metric | Hydraulics | Electric Motors |

|---|---|---|

| Power Density | ★★★★★ (Compact & mighty) | ★★★☆☆ |

| Overload Safety | Pressure relief valves | Risk of burnout |

| Precision Control | Smooth variable force | Stepped increments |

| Shock Resistance | Fluid absorbs spikes | Gear damage risk |

Case Study: SpaceX’s rocket thrust vector control uses hydraulics for a reason – 150,000 lbs of instant force adjustment in a cryogenic environment.

Conclusion: The Physics That Lifts Civilizations

From dentist chairs to the International Space Station’s robotic arm, Pascal’s Law remains humanity’s quiet force amplifier. It embodies engineering elegance: a simple principle scaled to move planets. Next time you see a fire truck ladder reaching 10 stories high, remember – it’s not steel muscles doing the work, but confined oil transmitting a firefighter’s courage through an unbreakable law of physics.

“Give me a lever and a place to stand, and I shall move the world.” – Archimedes

Pascal would add: “…and a hydraulic cylinder to make it effortless.”