1. Introduction

Hydraulic systems are the backbone of countless industrial and mobile applications, from construction machinery to aerospace systems. At the heart of these systems lie hydraulic hoses—flexible, high-strength components that enable fluid transfer under extreme pressure. Understanding their functionality, types, and maintenance requirements is critical for ensuring operational safety, efficiency, and longevity . This blog provides a detailed exploration of hydraulic hoses, including selection criteria, testing methods, and troubleshooting techniques.

2. What Are Hydraulic Hoses?

Hydraulic hoses are flexible tubes designed to convey hydraulic fluids between components in a system. They are typically constructed with three layers:

- Inner Tube : Made of synthetic rubber or thermoplastic to withstand fluid compatibility .

- Reinforcement Layer : Braided or spiral-wound steel wires for pressure resistance.

- Outer Cover : A protective layer against abrasion, UV exposure, and environmental damage .

These hoses are indispensable in applications requiring movement flexibility, such as excavators, agricultural machinery, and aircraft landing gear .

3. How Do Hydraulic Hoses Work?

Hydraulic hoses operate by transferring pressurized fluid between system components (e.g., pumps, actuators, valves). When hydraulic fluid flows through the hose, it transmits energy, enabling mechanical actions like lifting, steering, or braking. The hose’s reinforcement layers counteract the internal pressure, preventing rupture while maintaining flexibility .

4. Types of Hydraulic Hoses

Hydraulic hoses vary by design, material, and pressure capacity:

- SAE Standard Hoses : Comply with Society of Automotive Engineers specifications for high-pressure applications .

- Thermoplastic Hoses : Lightweight and chemical-resistant, ideal for low-to-medium pressure systems .

- Wire-Braid Hoses : Reinforced with braided steel wires for high-pressure environments.

- Spiral-Wire Hoses : Multi-layered spiral-wound wires for ultra-high-pressure scenarios.

- Stainless Steel Hoses : Corrosion-resistant for extreme temperatures or chemical exposure .

5. How to Select the Right Hydraulic Hose

Key considerations include:

- Pressure Requirements : Match the hose’s working pressure to the system’s maximum demands.

- Material Compatibility : Ensure the hose resists degradation from hydraulic fluids (e.g., oil, water) and environmental factors .

- Size and Fit : Select the correct inner diameter, length, and fitting type (e.g., JIC, ORFS) to avoid flow restrictions or leaks.

- Application Demands : Mobile equipment may prioritize flexibility, while industrial systems may emphasize abrasion resistance .

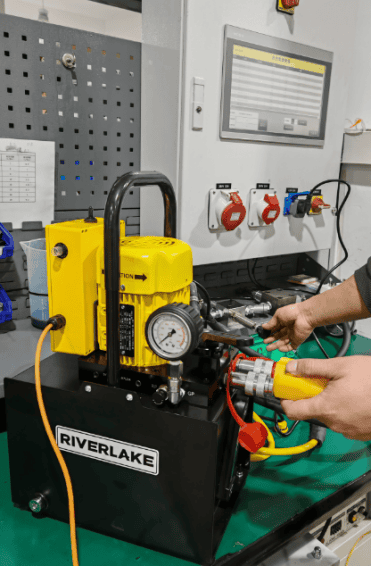

6. How to Test a Hydraulic Hose

Testing ensures safety and reliability:

- Pressure Testing : Gradually increase internal pressure until the hose bursts, recording the failure point .

- Leak Detection : Use visual inspections, ultrasonic sensors, or dye tests to identify leaks .

- Bend Radius Evaluation : Verify compliance with minimum bend radius standards to prevent kinking .

7. How Many Years Do Hydraulic Hoses Last?

Most hoses last 2–10 years, depending on:

- Operating pressure and temperature.

- Exposure to UV light, vibration, or corrosive substances.

- Frequency of maintenance and adherence to service intervals .

8. How to Identify a Faulty Hydraulic Hose

Warning signs include:

- External leaks, cracks, or bulges in the outer cover.

- Fluid discoloration or unusual system vibrations.

- Reduced system performance (e.g., slower actuator movement) .

9. When Should a Hydraulic Hose Be Replaced?

Replace hoses immediately if:

- Visible damage (e.g., fraying, corrosion) occurs.

- The hose exceeds its recommended service life.

- Leaks recur despite repairs .

10. Common Defects in Hydraulic Hoses

Frequent issues include:

- Abrasion : Caused by friction against machinery parts .

- Cracking : Due to ozone exposure or extreme temperatures.

- Internal Erosion : Particulate contamination wearing the inner tube.

- Fitting Failures : Improper crimping or corrosion at connection points .

11. How to Stop a Hydraulic Hose from Leaking

Preventive measures:

- Tighten fittings or replace worn seals .

- Install protective sleeves to reduce abrasion .

- Use clamps or sealants for emergency leak repairs .

12. What Happens When a Hydraulic Hose Fails?

Failures can lead to:

- Catastrophic system downtime and equipment damage.

- Safety hazards, such as high-pressure fluid injection injuries.

- Environmental contamination from spilled hydraulic fluid .

13. How to Repair a Hydraulic Hose

Repair options:

- Temporary Fixes : Clamps or sealants for immediate leak control .

- Permanent Repairs : Replace damaged sections with crimped fittings using professional equipment .

14. Conclusion

Hydraulic hoses are critical to system performance and safety. Proper selection, regular testing, and proactive maintenance are essential to mitigate risks and extend service life. By adhering to industry standards and leveraging expert guidance, operators can ensure reliable hydraulic system operation in even the harshest environments .