Tunnel Boring Machines (TBMs) represent one of the most sophisticated feats of mechanical, hydraulic, and geotechnical engineering, enabling the construction of underground networks with millimeter precision. For hydraulic engineers, these machines are a testament to the power of high-pressure fluid systems driving massive linear and rotary motion. This guide delves into the technical intricacies, historical evolution, and industrial applications of TBMs, providing a rigorous analysis tailored for engineering professionals.

1. What is a Tunnel Boring Machine?

A Tunnel Boring Machine (TBM) is a fully integrated excavation system designed to bore through soil and rock while simultaneously installing tunnel supports. Unlike conventional drill-and-blast methods, TBMs perform:

- Full-face excavation: Circular cross-section drilling in a single pass .

- Continuous support: Installation of precast segments or rock reinforcement behind the cutterhead.

- Automated muck handling: Conveyor or slurry systems for debris removal.

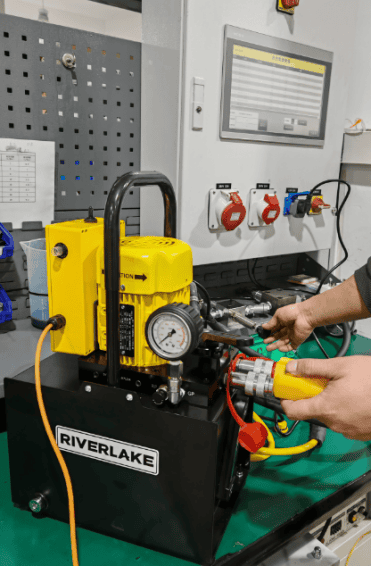

Core Hydraulic Systems:

- Thrust Cylinders: Generate up to 25,000 kN of force to advance the cutterhead into the face.

- Gripper Systems (Open TBMs): Hydraulic “shoes” anchor against tunnel walls to react thrust forces in hard rock .

- Segment Erectors: Precision manipulators placing 10-ton concrete segments with ±5mm tolerance.

2. Historical Evolution: From 19th-Century Prototypes to Digital Giants

Pioneering Era (1853–1950s)

- 1853: Charles Wilson’s first TBM advanced only 10 feet in Massachusetts’ Hoosac Tunnel before failure .

- 1952: James Robbins’ modern shield machine succeeded at South Dakota’s Oahe Dam, proving TBM viability .

Modernization (1960s–2000s)

- 1988: 11 TBMs excavated the 50 km Channel Tunnel at record speeds (UK: 113 m/day; France: 57.6 km total) .

- 1997: China’s import of German TBMs for Qinling Railway Tunnel catalyzed domestic TBM development .

21st-Century Innovations

- 2020: The Boring Company’s Prufrock TBM targets 10–15× faster excavation than conventional machines using modular design and continuous tunneling .

- 2021: China’s “Funing Hao” hard-rock TBM achieved 90-meter curves at 9.53m diameter, enabling complex hydropower tunnels .

3. TBM Costs: Capital Investment vs. Operational Economics

TBM pricing scales nonlinearly with diameter and geological adaptability:

Table: TBM Cost Breakdown by Diameter Class

| Diameter Class | Range (meters) | Typical Cost (USD) | Primary Applications |

|---|---|---|---|

| Micro | 0.2–2.0 | $500K–$5M | Utility pipelines, sewers |

| Small | 2.0–4.2 | $5M–$10M | Metro tunnels, water conduits |

| Large | 7.0–12.0 | $15M–$30M | Highway tunnels, rail crossways |

| Mega | >12.0 | $30M–$100M+ | Subsea tunnels (e.g., Tokyo Bay) |

Lifetime Economics:

- Usage Life: 4–15 km before major overhaul .

- Operational Cost: $1M–$3M/month including power, labor, and maintenance.

4. TBM Types & Technical Differentiation

Hard-Rock TBMs

- Open Gripper TBMs: Use hydraulic grippers for thrust reaction in stable rock. Deploy rock bolts/steel arches for support (e.g., Qinling Tunnel) .

- Single-Shield TBMs: Rely on segmental lining for thrust; ideal for fractured rock.

- Double-Shield TBMs: Hybrid gripper/shield system enabling continuous tunneling—advance during segment installation .

Soft-Ground Shield TBMs

- Earth Pressure Balance (EPB): Pressurize excavated soil to balance groundwater. Critical for urban metros (e.g., China’s first EPB in 2008) .

- Slurry Shield (SPB): Use bentonite slurry to stabilize aquatic faces (e.g., Wuhan Yangtze River Tunnel) .

Hybrid & Specialized TBMs

- Multi-Mode TBMs: Switch between EPB/SPB/TBM modes mid-tunnel using convertible cutterheads .

- Rectangular/U-Shaped TBMs: Minimize urban excavation footprints (e.g., Hong Kong drainage tunnels) .

5. Advantages: Why TBMs Dominate Long Tunnels

- Speed: 3–10× faster than drill-and-blast; record: 1,650 m/month (Wanjiazhai Tunnel) .

- Safety: Eliminate blast-related hazards and reduce manpower in high-risk zones.

- Precision: Laser-guided steering maintains ±25mm alignment over 10 km bores.

- Surface Impact: Minimal vibration/subsidence—critical under cities (e.g., London Crossrail).

6. Disadvantages: Engineering Constraints

- Geological Inflexibility:

- Hard-rock TBMs stall in fault zones (e.g., Taiwan’s Hsuehshan Tunnel collapse, 1991) .

- EPBs require soil conditioning in coarse gravel.

- Logistical Challenges:

- Assembly weight: Up to 4,500 tons (17.6m-diameter TBM for Hong Kong-Zhuhai-Macau Bridge) .

- Site footprint: 150×50m for launch facilities .

- Capital Intensity: $100M+ investments necessitate project lengths >3 km for ROI .

7. Top 10 Global TBM Manufacturers

Table: Manufacturer Capability Matrix

| Company | HQ | Key Technologies | Notable Projects |

|---|---|---|---|

| Herrenknecht AG | Germany | Mixshield (EPB/SPB hybrids), Vertical TBMs | Gotthard Base Tunnel, Channel Tunnel |

| Robbins | USA | High-pressure rock TBMs (>300 MPa UCS) | Qinling Railway Tunnel |

| China Railway Equipment (CREG) | China | Multi-mode TBMs, Frozen-ground TBMs | Singapore Metro, Mumbai Coastal Road |

| Hitachi Zosen | Japan | Rectangular EPBs, Subsea slurry shields | Tokyo Bay Aqua-Line |

| The Boring Company | USA | Prufrock (high-speed modular TBM) | Las Vegas Convention Center Loop |

| Komatsu | Japan | Micro-TBMs (<1m diameter) | Osaka sewerage network |

| Terratec | Australia | Compact hard-rock TBMs for mining | Snowy Mountains Hydro |

| Kawasaki Heavy Industries | Japan | Cutterhead-driven articulation systems | Seikan Tunnel (Japan) |

| STEC | China | Slurry TBMs for boulder-rich strata | Wuhan Metro Line 7 |

| Lovsuns | China | EPB TBMs for soft soils | Bangkok Blue Line |

8. Troubleshooting & Maintenance: Maximizing Uptime

Critical Failure Modes

- Cutter Wear: Disc cutters degrade after 50–200 hours in quartzite (>250 MPa UCS). Monitoring requires torque/pressure trend analysis .

- Seal Leaks: Hydraulic oil contamination from grit ingress—mitigated by redundant wiper seals and 10μm filtration.

- Steering Drift: Asymmetric ground loading misaligns thrust cylinders. Corrected via grouting weak zones and recalibrating guidance systems.

Predictive Maintenance Protocols

- Vibration Analysis: Detect bearing/cutter imbalance at early stages (ISO 10816 standards).

- Oil Debris Monitoring (ODM): Track ferrous particles in hydraulic fluid to predict pump failures.

- Digital Twins: Real-time FEA models predict stress hotspots using cutterhead torque and advance rate data .

9. The Future: Automation and Extreme Geology

- AI-Driven TBMs: CREG’s smart TBMs integrate geophysical probing sensors and deep learning algorithms to adjust thrust/torque 10 seconds ahead of changing rock .

- High-Speed Tunneling: The Boring Company targets 1 km/week speeds with Prufrock’s continuous mucking and segment installation .

- Deep-Earth TBMs: Designed for >100°C temperatures and 50 MPa rock stresses in geothermal or mining projects.

Conclusion: The Hydraulic Heart of Underground Development

Tunnel Boring Machines exemplify the synergy between hydraulic engineering and geomechanics. While their capital intensity and geological constraints remain challenges, innovations in multi-mode adaptability, intelligent control, and high-pressure cutter technology continue to expand their domain. For hydraulic specialists, TBMs offer a frontier for optimizing cylinder efficiency, seal resilience, and power density—pushing the boundaries of what’s possible beneath our feet.

“The TBM is more than a machine—it’s a moving factory, integrating excavation, logistics, and construction into a single, relentless flow of progress.” — Geotechnical Engineering Handbook, 2023.