Hydraulic cylinders are the backbone of numerous industrial and mobile applications, converting hydraulic pressure into mechanical force and motion. As a hydraulic engineer specializing in designing cylinders for working pressures ranging at 70 MPa, I understand the intricacies and importance of these versatile components. This comprehensive guide aims to delve into the fundamentals, purposes, calculations, types, selection criteria, and pairing considerations for hydraulic cylinders, ensuring you have all the insights necessary to make informed decisions about your hydraulic systems.

What is a Hydraulic Cylinder?

A hydraulic cylinder, simply put, is a mechanical actuator that uses hydraulic fluid to generate linear force and motion. It consists of a cylindrical barrel, a piston connected to a piston rod, and seals to prevent fluid leakage. When pressurized hydraulic fluid is introduced into one end of the cylinder, it forces the piston to move in the opposite direction, thereby transmitting force and motion to the connected load.

Key Components

- Cylinder Barrel: Houses the piston and provides a sealing surface.

- Piston: Separates the fluid chambers and transfers force to the piston rod.

- Piston Rod: Connects the piston to the load and transmits force outside the cylinder.

- Seals: Prevent fluid leakage, maintaining system efficiency and pressure.

- Ports: Allow fluid to enter and exit the cylinder, controlling piston movement.

- Head/Cap: Closes one end of the cylinder barrel and supports the piston rod bearing or guide bushes.

What is the Purpose of the Cylinder?

Hydraulic cylinders serve a multitude of purposes across various industries, including construction, manufacturing, agriculture, and marine applications. Their primary role is to convert fluid power into mechanical energy, enabling tasks such as:

- Linear Actuation: Moving loads in a straight line, from pushing and pulling to lifting and lowering.

- Force Amplification: Applying significant forces to overcome resistance or manipulate heavy objects.

- Precision Control: Providing accurate positioning and speed control in automated systems and robotic arms.

- Compact Power Transmission: Offering high power density in a compact package, ideal for space-constrained environments.

What is the Formula for Calculating a Hydraulic Cylinder?

Understanding the basic calculations for hydraulic cylinders is crucial for designing and selecting the right cylinder for your application. Key formulas include:

Force Calculation

F = A x P

where:

- ( F ) = Force (in Newtons, N)

- ( A ) = Effective piston area (\( \pi \times r^2 \), in square meters, \( m^2 \))

- ( P ) = Pressure (in Pascals, Pa)

Velocity Calculation

v = Q/A

where:

- ( v ) = Velocity of the piston (in meters per second, \( m/s \))

- ( Q ) = Flow rate of hydraulic fluid (in cubic meters per second, \( m^3/s \))

- ( A ) = Effective piston area

Work Done

W = F X d

where:

- ( W ) = Work done (in Joules, J)

- ( F ) = Force

- ( d ) = Distance traveled by the piston (in meters, ( m ))

These formulas help engineers determine the cylinder size, required fluid pressure, and flow rates needed to achieve desired outputs in their applications.

Types of Hydraulic Cylinders and Where Are They Used?

Hydraulic cylinders come in various types, each tailored for specific applications and performance requirements. Here’s an overview of the most common types and their use cases:

Tie Rod Cylinders

- Features: External tie rods hold the cylinder barrel and end caps together.

- Applications: General-purpose use in construction equipment, presses, and agricultural machinery due to their versatility and cost-effectiveness.

Welded Cylinders

- Features: Barrel and end caps are welded together, providing a compact, seamless design.

- Applications: High-pressure applications and space-constrained environments, such as in mining equipment and compact machinery.

Telescopic Cylinders

- Features: Multiple nested cylinders extend and retract in stages, providing extended reach.

- Applications: Aerial platforms, cranes, and dump trucks where extended reach and variable stroke lengths are required.

Piston Accumulator Cylinders

- Features: Combine the functions of a cylinder and an accumulator, storing energy in compressed gas.

- Applications: Hydraulic power units, shock absorbers, and energy storage systems in mobile equipment.

Rotary Actuators

- Features: Convert linear cylinder motion into rotational output via gears, racks, and pinions.

- Applications: Rotary motion requirements in automation systems, packaging machinery, and robotic applications.

How to Choose a Hydraulic Cylinder?

Selecting the right hydraulic cylinder involves considering several factors to ensure optimal performance and reliability. Here’s a step-by-step guide:

1. Define Application Requirements

- Force and Load Requirements: Determine the maximum force needed and the type of load (static, dynamic, or impact).

- Stroke Length: Measure the distance the piston needs to travel to complete the task.

- Speed and Acceleration: Establish the required movement speed and acceleration rates.

- Mounting and Orientation: Decide how and where the cylinder will be mounted (horizontal, vertical, or inclined).

- Environmental Conditions: Consider temperature extremes, contamination, and exposure to corrosive materials.

2. Select Cylinder Type

- Choose the cylinder type based on the application requirements and space constraints (tie rod, welded, telescopic, etc.).

3. Determine Material and Seals

- Select materials compatible with the operating environment and fluid type (steel, aluminum, stainless steel).

- Choose seals suitable for the operating pressure and fluid compatibility to prevent leaks and maintain efficiency.

4. Evaluate Port Sizes and Connections

- Ensure port sizes and connections match your hydraulic system’s specifications for proper fluid flow and pressure handling.

5. Consider Accessories and Options

- Assess the need for accessories such as position sensors, cushioning devices, and rod wipers to enhance cylinder performance and longevity.

6. Verify Manufacturer’s Specifications

- Cross-check your selected cylinder’s specifications with the manufacturer’s data to ensure compliance with your design requirements and safety standards.

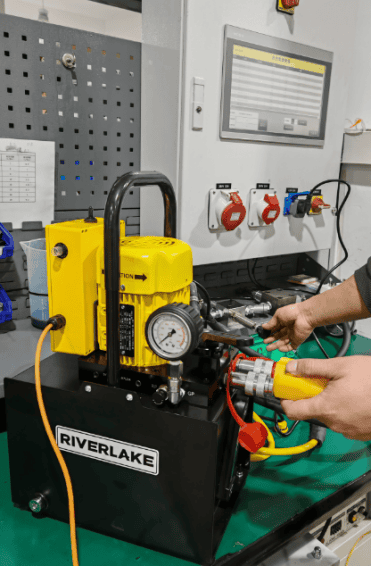

How to Choose a Suitable Hydraulic Pump for My Hydraulic Cylinder

Pairing the right hydraulic pump with your cylinder ensures efficient fluid delivery, pressure control, and system reliability. Here’s a guide to selecting the appropriate pump:

1. Determine Flow Rate Requirements

- Calculate the required flow rate based on the cylinder’s speed and effective piston area using the velocity formula ( v = Q/A)

2. Consider Pressure Capabilities

- Ensure the pump can generate sufficient pressure to meet the cylinder’s force requirements and system design pressure limits.

3. Evaluate Pump Types

- Fixed Displacement Pumps: Ideal for constant torque applications and systems requiring precise control of flow and pressure.

- Variable Displacement Pumps: Suitable for variable load conditions, offering adjustability in flow and pressure to match system demands efficiently.

- Gear Pumps: Cost-effective for low-pressure applications due to their simplicity and reliability.

- Piston Pumps: Provide high-pressure capabilities and precise control, making them suitable for heavy-duty industrial applications.

4. Efficiency and Life Expectancy

- Choose pumps with high efficiency ratings to minimize energy consumption and reduce operational costs. Consider pump life expectancy based on expected duty cycles and maintenance intervals.

5. System Compatibility

- Ensure the pump’s ports, mountings, and control options are compatible with your existing hydraulic system infrastructure and controls.

6. Consult Manufacturer Recommendations

- Reference the manufacturer’s guidelines for pump selection, ensuring compatibility with your cylinder specifications and system requirements.