1. Introduction: The Critical Role of Bridge Bearings

In 2018, the Xiamen Bridge in China faced a costly lesson in infrastructure neglect: localized bearing failure triggered widespread structural degradation, necessitating a full-scale retrofit to restore safety and functionality . This case underscores the critical yet often overlooked role of bridge bearings—the “movable joints” of a bridge—that balance static loads, dynamic forces, and thermal displacements while ensuring structural resilience. Bearings act as the interface between a bridge’s superstructure (deck) and substructure (piers or abutments), enabling controlled movement without compromising stability . Without proactive maintenance, even minor bearing defects can cascade into systemic failures, demanding extensive—and expensive—repairs.

2. What is a Bridge Bearing?

A bridge bearing is a mechanical device designed to transmit vertical loads (e.g., weight of the deck and traffic) while accommodating horizontal movements caused by thermal expansion, seismic activity, or wind . Key components include:

- Upper/Lower Steel Plates : Distribute loads evenly across the bearing surface .

- Sliding Layer : Typically made of polytetrafluoroethylene (PTFE) or ultra-high-molecular-weight polyethylene (UHMWPE), these materials minimize friction during translational movements .

- Sealing System : Dust-proof covers and corrosion-resistant coatings protect internal components from environmental degradation .

This modular design ensures bearings can handle both static and dynamic forces, acting as a bridge’s “shock absorber” against unpredictable stresses.

3. Why Do Bridges Need Bearings? Core Functions

Bridges endure complex forces that demand precise load management. Bearings fulfill three primary roles:

- Load Transfer : Vertically, they distribute dead and live loads (e.g., vehicle weights) to piers and abutments, preventing stress concentrations that could fracture concrete or steel . For instance, a continuous girder bridge might experience 20% higher localized stresses without proper load distribution .

- Accommodating Movements :

- Thermal Expansion : A 100-meter steel-concrete composite beam can expand by 40 mm with a 40°C temperature swing; bearings absorb this displacement .

- Dynamic Loads : Vehicle braking or wind gusts induce horizontal shifts, which sliding bearings mitigate through low-friction interfaces .

- Reducing Secondary Stresses : By releasing rotational constraints, bearings prevent cracks in curved bridges—structures prone to torsional stresses under temperature gradients .

4. Types of Bridge Bearings: Materials & Mechanisms

| Type | Material/Design | Application Scope | Limitations |

|---|---|---|---|

| Elastomeric Bearings | Layered rubber + steel plates (CR/Neoprene) | Short-to-medium span simply supported beams | Aging reduces shear deformation capacity |

| Pot Bearings | Steel pot + rubber pad + PTFE plate | Long-span continuous beams/curved bridges | Corrosion in steel pots compromises seals |

| Spherical Bearings | Stainless steel concave surface + PTFE | Cable-stayed bridges/seismic zones | Requires high-precision installation |

| Sliding Plate Bearings | UHMWPE/PTFE composites | Heavy-haul railway bridges | Wear necessitates frequent replacement |

Each type balances flexibility and rigidity, tailored to specific structural demands.

5. Life Expectancy: When Do Bearings Fail?

Bearing lifespans vary widely:

- Elastomeric Bearings : 20–30 years; chloroprene rubber outperforms natural rubber in ozone-rich environments .

- Pot Bearings : 30–50 years; longevity hinges on anti-corrosion coatings, which degrade under coastal chloride exposure .

Accelerated Degradation Factors :

- Chemical : Acid rain (pH < 4.5) or deicing salts reduce rubber elasticity by 30% after 90 days of H₂SO₄ immersion .

- Mechanical : Overloaded trucks (>55 tons) cause permanent PTFE plate deformation, increasing friction coefficients by 40% .

- Environmental : Chloride ingress in marine environments accelerates steel component rusting, reducing load capacity by 25% within 5 years .

Regular inspections every 1–5 years are critical to detect early signs of failure, such as cracking or misalignment .

6. Step-by-Step: Bridge Bearing Replacement Techniques

Critical Preparations

- Drone-Based Inspections : High-altitude bearings on piers up to 50 meters are now surveyed via drones, eliminating risky scaffolding .

- Condition Assessment : JTG/T H21 standards categorize bearing health into five grades; replacements are prioritized if cracks exceed 2 mm or rotation exceeds 0.02 radians .

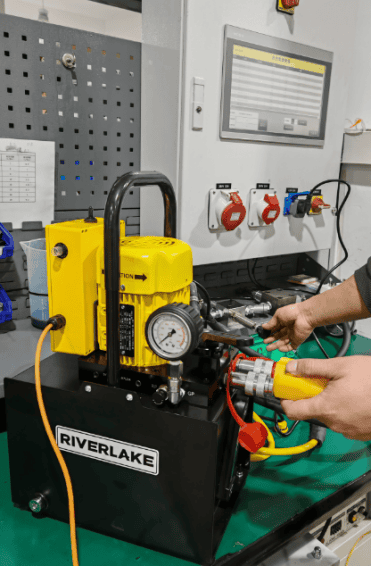

Synchronous Jacking Technology from ULTPRE

- Single-Pier Lifting : For simply supported beams, hydraulic jacks raise the superstructure ≤5 mm per pier to replace elastomeric bearings .

- Proportional Lifting : Continuous beams require multi-pier synchronization, maintaining height differences <0.5 mm to prevent torsional stress .

Traffic Management Strategies

- Non-Interruption Schemes : Axle load limits (<55 tons) and partial lane closures enable repairs on urban overpasses .

- Full Closure Conditions : Mandated for bridges with expansion joint gaps >5 mm or sharp curves (R ≤ 500 m), where lateral instability risks are high .

7. Emerging Trends in Bearing Maintenance

- Smart Bearings : Piezoelectric sensors (d33-mode PZT) embedded in pot bearings monitor real-time stress distribution, predicting failures with 92% accuracy .

- Eco-Friendly Materials : Pure polyurea coatings replace traditional rubber, resisting UV degradation 3× longer while reducing VOC emissions .

- Robotic Replacement : BIM-integrated jacking systems automate force adjustments during bearing swaps, achieving <0.3 mm positional accuracy .

These innovations promise to transform reactive maintenance into predictive, data-driven workflows.

8. Conclusion: Proactive Maintenance Saves Costs

Bearing failures trigger chain reactions: uneven stress distribution can twist girders, inducing cracks in adjacent piers . To mitigate risks, agencies should adopt two practices:

- Five-Year Inspection Cycles : Coupled with drone-based diagnostics and vibration analysis .

- Digital Twin Archives : BIM models tracking bearing performance metrics enable lifecycle forecasting .

By prioritizing bearing health, engineers can extend bridge service lives by decades—avoiding the costly lessons of cases like the Xiamen Bridge .